KrosFlo® RS TFF Systems

WHEN EVERY DROP COUNTS

Ideal for mRNA and gene therapy solutions, KrosFlo® RS TFF Systems are engineered for maximum recovery. The combination of injection molded tubing, over-molded connections, and valve blocks significantly lowers hold-up volume.

WHEN EVERY DROP COUNTS

For mRNA, AAV, Lentivirus developers

Minimize hold-up volume with innovative valve block technology

Intelligent mixing even at the lowest working volume

ZERO MANUAL INTERVENTION

Automate from sanitization to recovery

Eliminate batch variation with end-to-end automation

READY TO SCALE FAST

For effortless scaling from 1/4" to 1"

Maintain processes while scaling to production

1滴1滴が大切

1滴1滴が大切

Minimize hold-up volume with innovative valve block technology

Ideal for mRNA and gene therapy solutions, KrosFlo® RS TFF Systems are engineered for maximum recovery.

The combination of injection molded tubing, over-molded connections, and valve blocks significantly lowers hold-up volume.

1滴1滴が大切

1滴1滴が大切

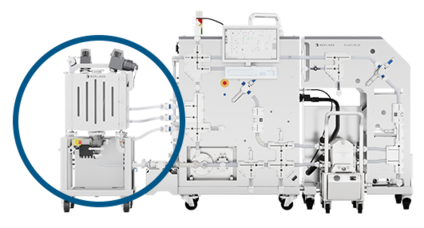

Intelligent mixing even at the lowest working volume

Innovative tulip tank technology delivers hold-up volumes as low as 1.5L with active mixing.

As fluid levels drop, the dual impellers independently adjust speed to reduce harmful surface interaction while automated valves adapt retentate flow to avoid damage upon entering the tank.

Tulip Tank cart available with KrosFlo® RS 30, 40, 50

ZERO MANUAL INTERVENTION

ZERO MANUAL INTERVENTION

Eliminate batch variation with end-to-end automation

Completely automate processes from start to finish without intervention.

Traditional single-use systems require manual manipulation due to the limited number of controlled valves. Additional controlled valves throughout the flowpath allow complete automation of processes.

Sanitization

- WFI/Buffer Flushing

- Integrity testing

Concentration

- Fed-Batch Concentration

- Batch Concentration

Recovery

- Product Recovery

- Clean-in-place

READY TO SCALE FAST

READY TO SCALE FAST

Maintain processes while scaling to production

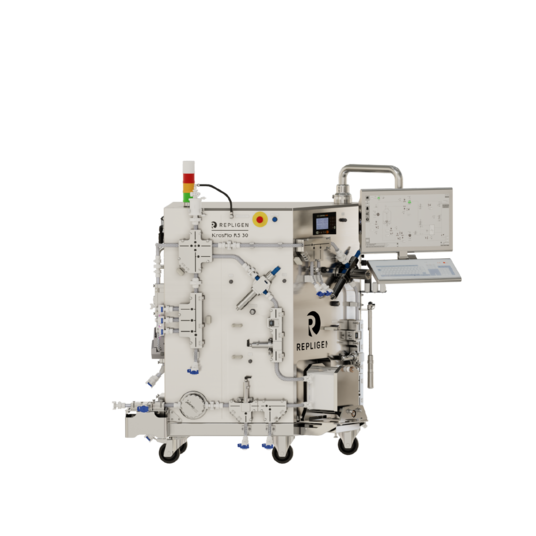

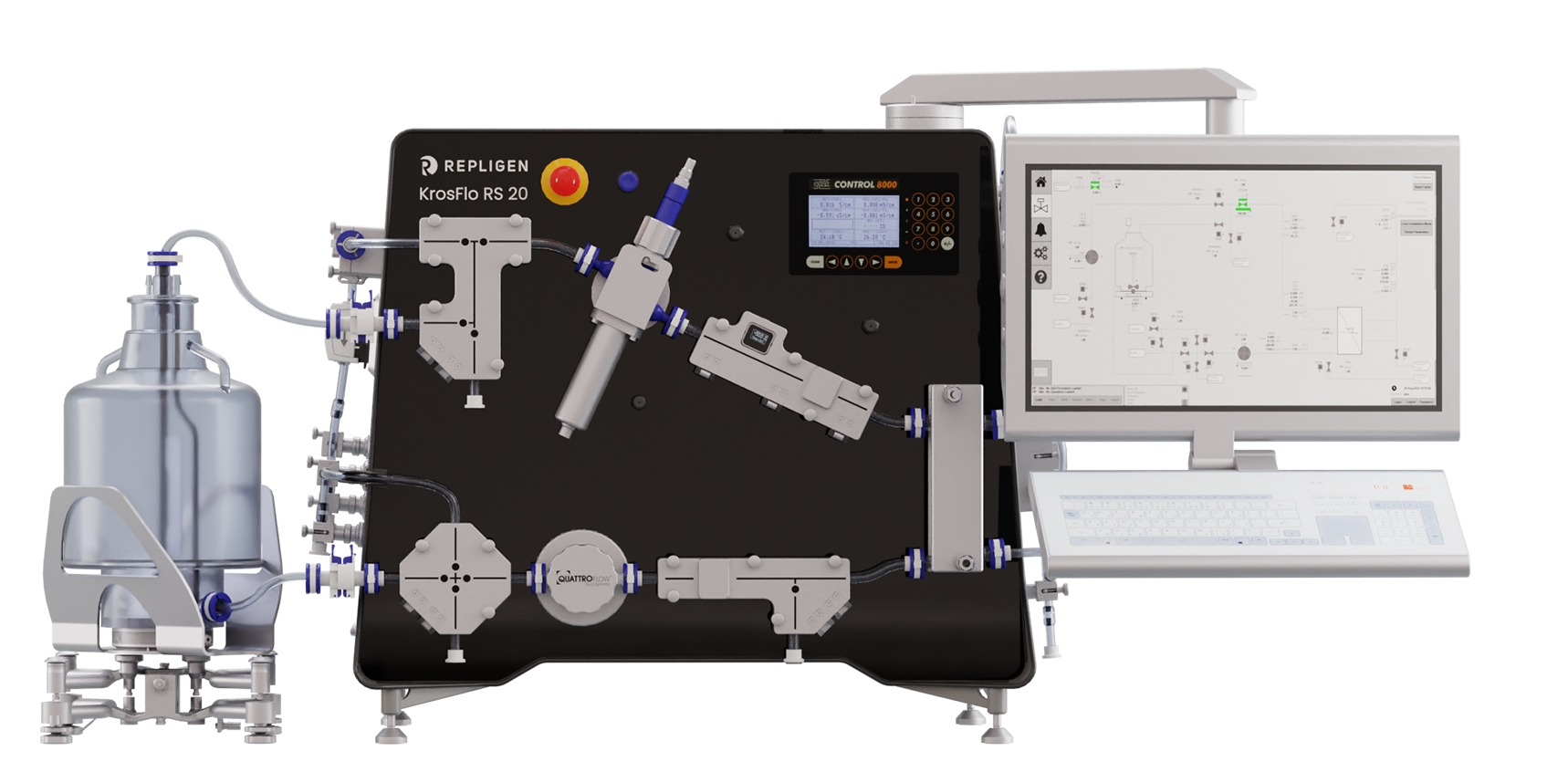

KrosFlo® RS 20

0.1 - 0.5 m²

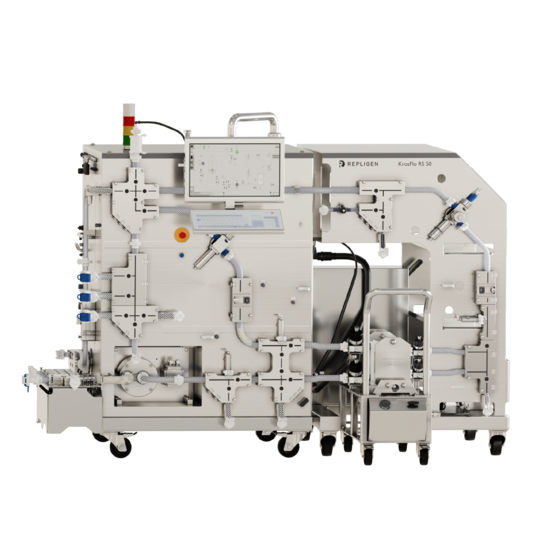

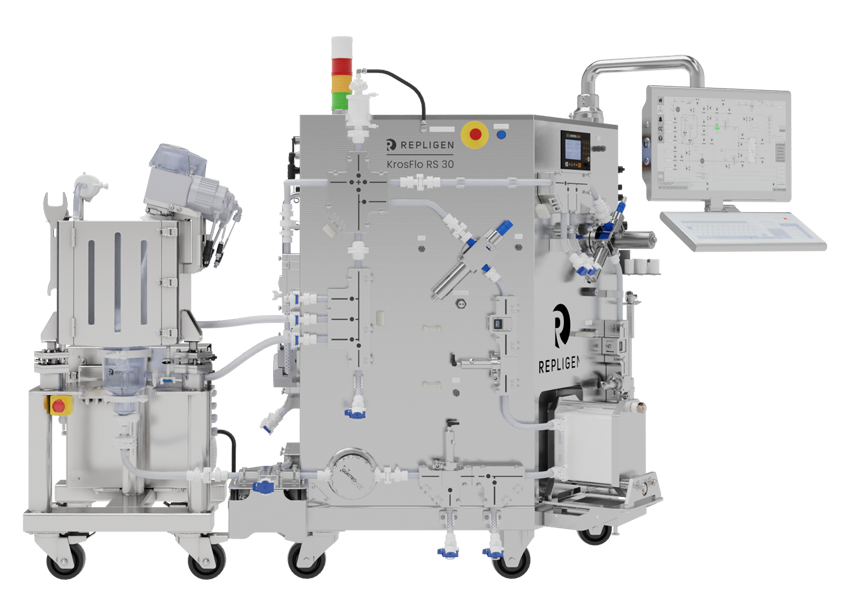

KrosFlo® RS 30

0.5 - 3 m²

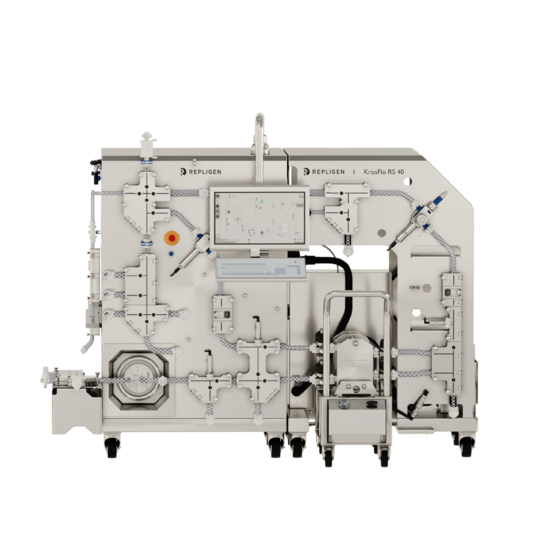

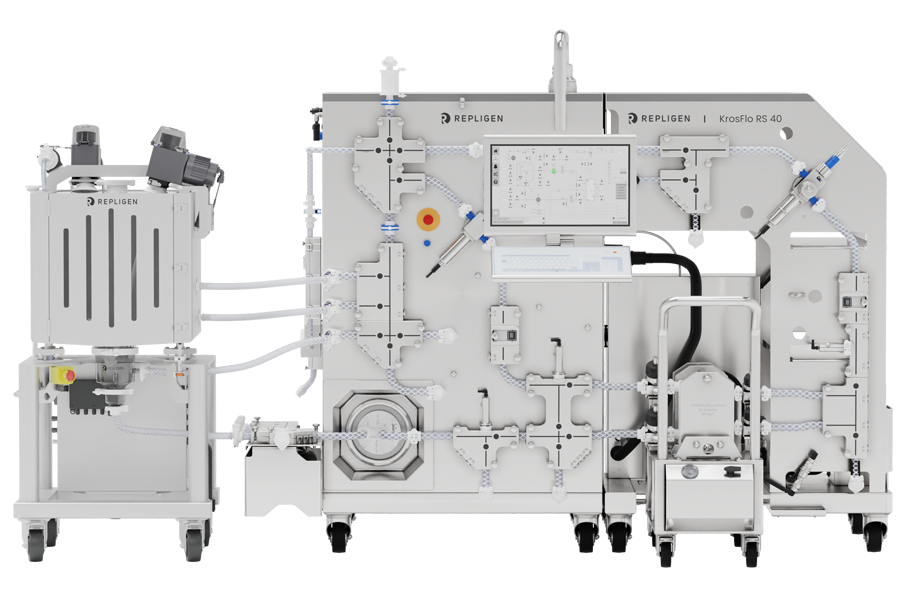

KrosFlo® RS 40

1 – 5 m²

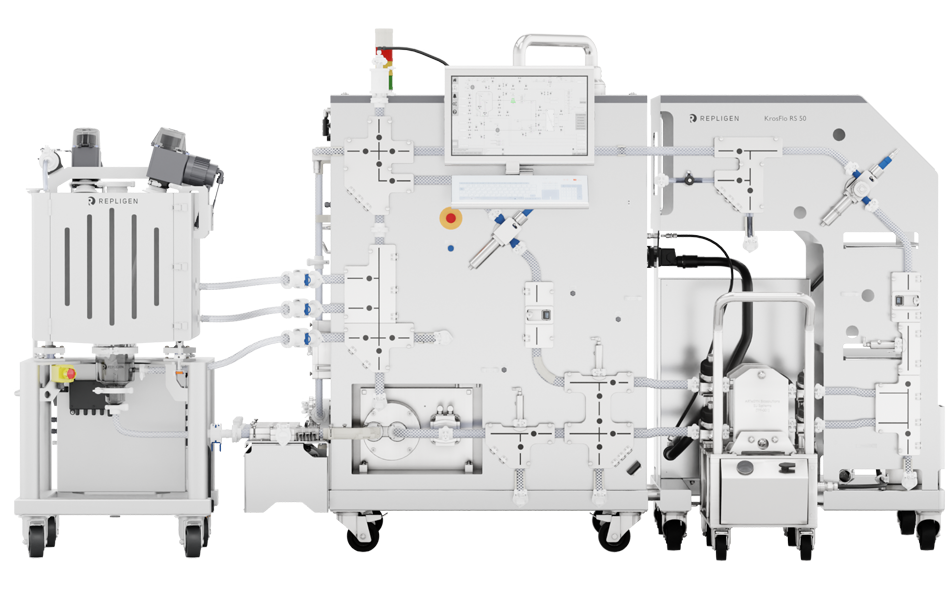

KrosFlo® RS 50

5 – 10 m²

Industrial grade components and extended automation allow for confident process scaling. With the same software, hardware, controls and cGMP compliance built into every system, process change challenges in scale-up are removed.

KrosFlo® RS TFF Systems

KrosFlo® RS Single-use Tangential Flow Filtration (TFF) Systems incorporate the most advanced engineering principles to achieve unprecedented automation, hold-up volume and process control. The unique tulip tank continuously measures sample volume and then adjusts dual impeller speeds and retentate routing to nearly eliminate foaming. Conceptualized as a platform, rather than a single system, a single architectural approachenables effortless scale-up from 1/4" to 1".

Click on the tabs to explore features of the different KrosFlo RS Systems.

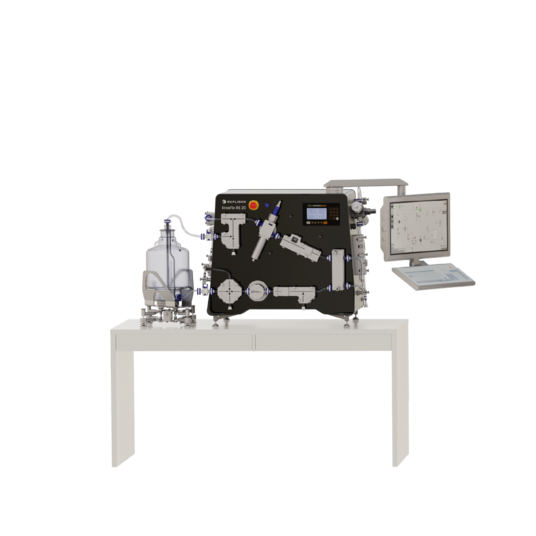

KrosFlo® RS 20 TFF System

Click on the links to explore different features.

KrosFlo® RS 30 TFF System

Click on the links to explore different features.

KrosFlo® RS 40 TFF System

Click on the links to explore different features.

KrosFlo® RS 50 TFF System

Click on the links to explore different features.

Error-free installation in minutes with pre-assembled flow paths

ProConnex Flow Paths, pre-assembled and specific to the KrosFlo® RS TFF System, are intuitively designed for simple, mistake-free installation. All system sensors are pre-calibrated and assembly is done in minutes with no confusing instructions.

Click on the left/right arrows or swipe to see flow path assembly steps for the different KrosFlo® RS TFF Systems.

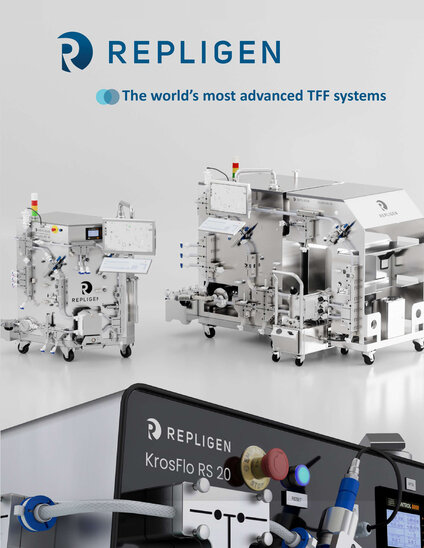

The world's most advanced TFF systems

In an era of new modalities, developers are striving to maximize efficiency.

The new KrosFlo® RS TFF systems by Repligen empower users through maximized recovery, full automation and effortless scaling.

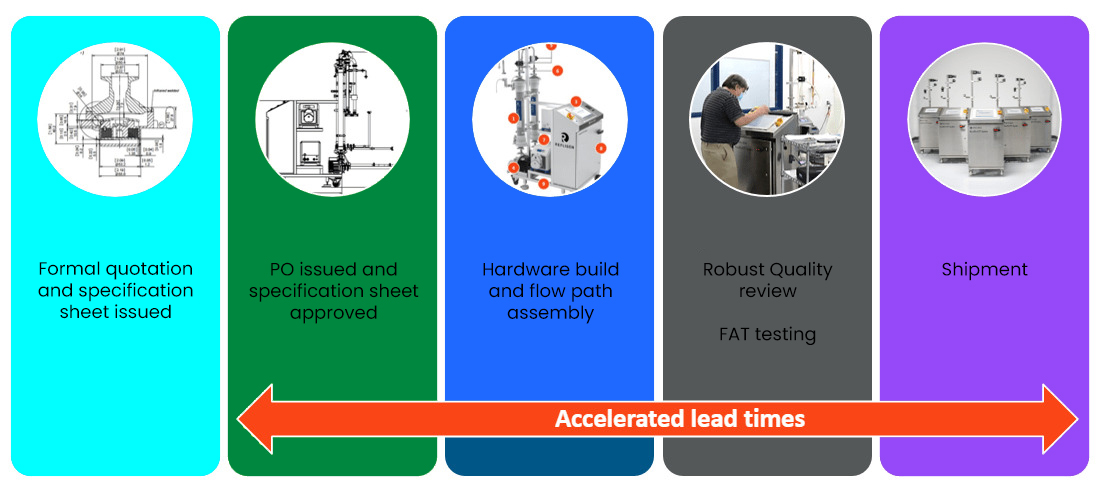

Manufacturing Centers of Excellence

Repligenは、ISO 9001品質管理システムに基づいて、バイオ医薬品業界向けの製品を開発・製造しています。高品質で安定した、堅牢な製品をタイムリーに提供し、お客様の事業継続性を保証することを重視しています。

Repligen manufacturing sites are located in Massachusetts, California, and New Jersey in the United States and in Sweden, France, The Netherlands, Germany and Estonia.

Expert Project Management

お客様第一。

サポートは、Repligenという企業の遺伝子に組み込まれています。弊社の目標は、卓越した顧客体験を提供すること、そしてRepligenの製品やサービスの適用や導入を効率よく成功に導くためにサポートすることです。

- Field Application Support

- カスタマーサービス

- フィールドサービスエンジニア