XCell® ATF Devices and Controllers

XCell® ATF Systems simplify and fast-track upstream intensification by providing an integrated solution consisting of an XCell® ATF Device, XCell® ATF Controller, software, tubing, pressure sensors and accessories. The family of Systems supports diverse applications across development from 1L to 5000 L.

XCell® ATF Device Size Selection Guide

Presented are hollow fiber filter areas, XCell® ATF Pump volumes, and typical bioreactor working volumes paired with each XCell ATF Device. Actual capacity and vessel size depend upon specific cell culture process conditions.

XCell® ATF Single-use Devices

XCell ATF 1 Single-use Device

XCell ATF 2 Single-use Device

XCell ATF 6 Single-use Device

XCell ATF 10 Single-use Device

XCell ATF Single-use Tubing Sets

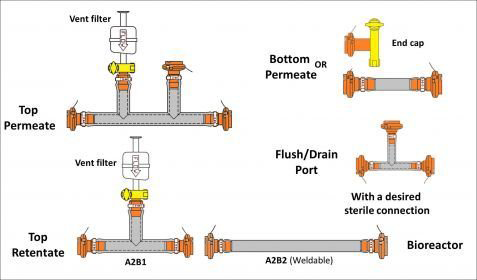

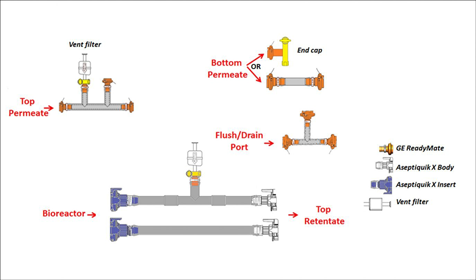

フィルターのウェッティング手順

XCell ATF Single-use Devices are supplied dry. To ensure robust filter performance, it is important to wet the filter prior to use. The XCell ATF Tubing Set and the suggested wetting protocols are designed to:

- ウェッティングプロセス中のエアポケット形成を最小限に抑えることで、効率的かつ完全なフィルターウェッティングが可能

- 無菌性を維持しつつ、使用前フィルターの完全性テストが可能

- Provide a means for evaluating the sterility of the XCell ATF device prior to establishing the bioreactor connection

- Allow change-out of the XCell ATF device during a cell culture run without interrupting the bioreactor or XCell ATF operation

XCell ATF Stainless Steel Devices

XCell ATF 2 Stainless Steel Device

XCell ATF 4 Stainless Steel Device

XCell ATF 6 Stainless Steel Device

XCell ATF 10 Stainless Steel Device

中空糸フィルターの取付方法

Watch the video on how to install a hollow fiber filter into an XCell ATF 10 stainless steel device.

XCell® Controllers

XCell Lab Controller

for use with:

XCell ATF 1 (SU)

XCell ATF 2 (SU,SS)

XCell ATF 4 (SS)

XCell LS Controller

for use with:

XCell ATF 4 (SS)

XCell ATF 6 (SU, SS)

XCell ATF 10 (SU, SS)

XCell C410 Controller

for use with:

XCell ATF 4 (SS)

XCell ATF 6 (SU, SS)

XCell ATF 10 (SU, SS)

XCell C410 Controller Cart

(optional)

Advancing Upstream Intensification Through Partnership

Repligen has partnered with Sartorius to integrate the XCell® ATF large scale controller technology into the Biostat 3G STR® bioreactor to advance Upstream Intensification for biopharmaceutical manufacturers.

XCell ATF devices by scale

|

|

|

||

|---|---|---|---|---|

|

XCell® ATF 1 |

XCell® ATF 2 |

XCell® ATF 4 |

||

| Typical Bioreactor size (L) | 0.5~2 | 2~10 | 10~50 | |

| Format | SU | SU, SS | SS | |

| Chemistry | PES | PES, PS | PES, PS | |

| Typical pore size SU | 0.2µ | 0.2µ | 0.2µ | |

| Typical pore size SS | NA | 0.2µ, 0.5µ, 50KDa | 0.2µ, 0.5µ, 50KDa | |

| Effective surface area (m2) | 0.022 | 0.13 | 0.77 | |

| Filter height (cm) | 60 | 60 | 30 | |

| Displacement volume (L) | 0.017 | 0.1 | 0.4 | |

| ATF flow range (Lpm) | 0.008~0.140 | 0.4 - 1.5 | 3~8 | |

| Typical scalable flow/fiber and filtrate rate | 12 mL/min/fiber and 4-6 LMH | |||

| コントローラー | XCell Lab Scale Controller |

|

||

|

|

|

|---|---|---|

|

XCell® ATF 4 |

XCell® ATF 6 |

|

| Typical Bioreactor size (L) | 10~50 | 50~200 |

| Format | SS | SU, SS |

| Chemistry | PES, PS | PES, PS |

| Typical pore size SU | 0.2µ | 0.2µ |

| Typical pore size SS | 0.2µ, 0.5µ, 50KDa | 0.2µ, 0.5µ, 50KDa |

| Effective surface area (m2) | 0.77 | 2.5 |

| Filter height (cm) | 30 | 60 |

| Displacement volume (L) | 0.4 | 1.3 |

| ATF flow range (Lpm) | 3~8 | 10~20 |

| Typical scalable flow/fiber and filtrate rate | ||

| コントローラー |

|

|

|

|

||

|---|---|---|---|

|

XCell® ATF 6 |

XCell® ATF 10 |

||

| Typical Bioreactor size (L) | 50~200 | 200~5000 | |

| Format | SU, SS | SU, SS | |

| Chemistry | PES, PS | PES, PS | |

| Typical pore size SU | 0.2µ | 0.2µ | |

| Typical pore size SS | 0.2µ, 0.5µ, 50KDa | 0.2µ, 0.5µ, 50KDa | |

| Effective surface area (m2) | 2.5 | 11 | |

| Filter height (cm) | 60 | 60 | |

| Displacement volume (L) | 1.3 | 6 | |

| ATF flow range (Lpm) | 10~20 | 30~80 | |

| Typical scalable flow/fiber and filtrate rate | 12 mL/min/fiber and 4-6 LMH | 12 mL/min/fiber and 4-6 LMH | |

| コントローラー |

|

|

|

リソース

Investigation of XCell ATF® Perfusion Technology for virus manufacturing process intensification at MSD Animal Health

Repligen Corporation

MSD Animal Health

July 2022