N-1 Perfusion

シードトレイン強化の一形態であるN-1灌流は、プロダクションバイオリアクター(N)の前段階のシードトレインステップ(N-1)で細胞増殖を強化することを意味します。既存のフェッドバッチベースのプロダクションスキームを維持しながら、より迅速で堅牢なプロセスを実現できます。

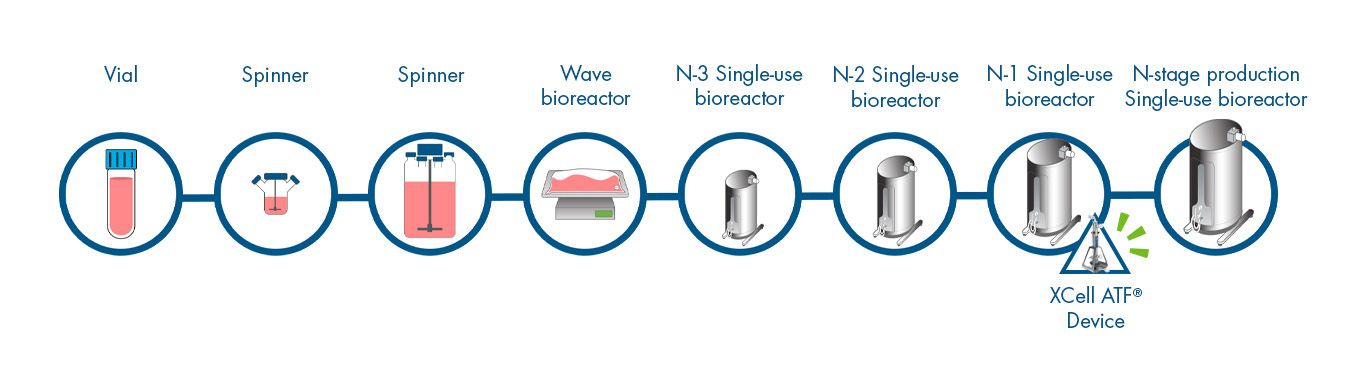

N-1 perfusion is done by attaching a cell retention device, such as the XCell ATF® Device, to the N-1 bioreactor to attain high cell density and viability. This seeds the N production bioreactor at a higher starting cell density and shortens the production bioreactor run time. The process dramatically increases facility output without direct change to the core Fed-Batch production process. A robust cell retention device is required to attain a high cell density inoculum for the production bioreactor.

The combination of implementation ease and productivity increase makes N-1 perfusion the most frequent starting point for upstream intensification. Once in place, further intensify the seed train by adding High Productivity Harvest (HPH) to the N bioreactor or transition to continuous.

Repligen solutions help overcome key challenges in N-1 perfusion, with hands-on process and implementation consultation from global Field Applications Specialists.

N-1 Perfusion Cell Culture Workflow

Click on the workflow link below to find productivity and throughput solutions you can implement today.

スループット向上と時間短縮

N-1 perfusion intensifies the Fed-Batch process, increasing facility throughput. Seeded at a higher initial density, cells in the N bioreactor grow faster, reach a higher max VCD and produce more product than traditional Fed-Batch. Harvest sooner and increase the number of batches per year as compared to a standard Fed-Batch process. Alternatively, maintain the N bioreactor run time to increase overall yield.

Maintain a Fed-Batch process

N-1 perfusion intensification increases N bioreactor productivity and throughput while maintaining a Fed-Batch process. No perfusion or media exchange of the N bioreactor is required, allowing the N bioreactor to maintain a single and discreet Fed-Batch harvest point.

Minimize validation impact

最小限のプロセス変更と規制編集で強化可能です。Nバイオリアクターには追加の機器接続が不要なため、生成中に培地交換が発生せず、細胞の生存率が高いため、通常は不純物の値が低くなります。

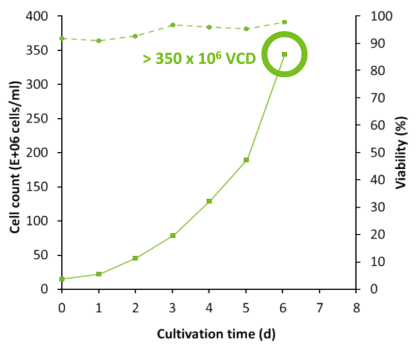

N Bioreactor reached 350 x 106 VCD

N-1 perfused Fed-Batch reached 350 million cells/mL VCD in just 6 days. In comparison, standard Fed-Batch achieved 30 million cells/mL viable cell density (VCD) over a course of 14 days. Productivity of the N bioreactor with N-1 perfusion increased 20X while maintaining viability above 90%.

Higher cell density and viability

- 10X VCD over Fed-Batch

- VCD as high as 350 x 106 cells/mL

- 生産時間を50%削減

- 20X increase in productivity

- COGを削減

N-1 Perfusion increased VCD 10X, reduced production time by 50%

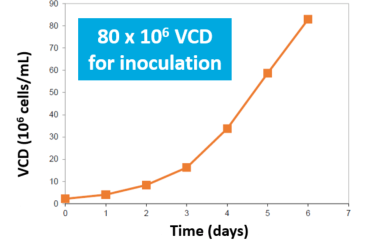

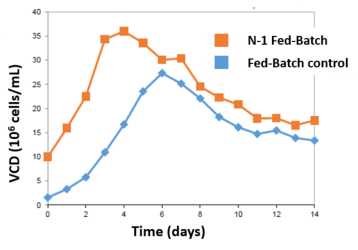

The perfused N-1 bioreactor cell density rapidly increased from 8 to 80 million cells/mL (10x VCD) in 4-5 days. Inoculation of the N bioreactor with the N-1 perfused culture established a 10X higher initial viable cell density over Fed-Batch (A). After 3 days, the N-1 inoculated bioreactor achieved 35 million VCD. In comparison, the control required 6 days to achieve 25 million VCD (B).

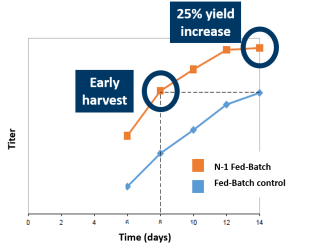

Leverage higher VCD to either increase throughput or increase yield. Harvest of the N-1 Fed-Batch bioreactor at day 8 was equivalent to harvesting the Fed-Batch control at day 14, saving 6 days of N bioreactor suite time (C). Alternatively, harvest the N-1 Fed-Batch process at day 14 for a 25% overall yield increase.

- N-1 bioreactor reached 10X VCD in 4-5 days

- N-1 perfused Fed-Batch bioreactor reached maximum VCD of 35 million compared to 25 million with traditional Fed-Batch

- Maximum VCD was achieved 3 days earlier

- 同じ収量を6日早く達成

- 14日目までに25%の収量向上を達成

N-1 Bioreactor VCD

Production Bioreactor VCD

バイオリアクター生成

お客様第一。

サポートは、Repligenという企業の遺伝子に組み込まれています。弊社の目標は、卓越した顧客体験を提供すること、そしてRepligenの製品やサービスの適用や導入を効率よく成功に導くためにサポートすることです。

- Field Application Support

- カスタマーサービス

- フィールドサービスエンジニア